Views: 0 Author: Site Editor Publish Time: 2026-01-30 Origin: Site

CNC (Computer Numerical Control) router machines have revolutionized the manufacturing industry by offering an unparalleled combination of efficiency and versatility. These machines have become indispensable tools for industries ranging from woodworking to plastics, sign-making, and aerospace. Through automated processes, CNC routers not only improve productivity but also open the door to more complex, customized, and precise work that would be difficult to achieve with traditional methods.

In this article, we will explore how CNC router machines excel in both efficiency and versatility, making them vital assets in today's fast-paced and competitive manufacturing environment.

One of the most significant advantages of CNC router machines is their ability to operate automatically once programmed. By using CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software, a CNC router can perform intricate cuts and designs without manual intervention. This automation significantly reduces labor time and eliminates human errors that can arise from fatigue or inexperience.

CNC routers can operate 24/7, performing tasks at a consistently high speed and quality. This automation leads to faster turnaround times, especially in high-volume production environments. Whether you're producing custom parts, detailed engravings, or large panels, CNC routers can maintain a steady workflow that traditional manual processes cannot match.

CNC routers are also efficient when it comes to setting up and changing over from one job to another. In traditional methods, changing tools or adjusting the setup can be time-consuming and often requires skilled labor. However, with a CNC router, the machine can easily switch between different cutting tools and adjust its operations via simple software updates. This reduces downtime and allows for quicker transitions between production runs, making the overall process more time-efficient.

Efficiency isn’t just about speed; it’s also about using materials effectively. CNC routers are programmed to cut with extreme precision, minimizing waste. By following precise cutting paths and adjusting tool paths according to the material’s thickness and type, CNC routers maximize the usage of the material. This is particularly important for industries dealing with expensive materials like composites, where every bit of waste counts.

By automating most of the production process, CNC routers reduce the need for manual labor. While a skilled technician may still be required for programming and machine maintenance, the routine cutting, shaping, and engraving tasks can be carried out by the machine itself. This reduces labor costs and allows operators to focus on tasks that require more skill or problem-solving.

CNC routers are incredibly versatile because they can work with a variety of materials. Some common materials that CNC routers can process include:

Wood: Used for cabinetry, furniture, and custom designs.

Plastics and Acrylics: Ideal for sign-making, display cases, and parts for consumer electronics.

Composites: Used for industries that require lightweight yet durable materials, such as aerospace and marine engineering.

This material flexibility allows businesses in different industries to adopt CNC routers for a wide variety of applications. From custom furniture to precision parts, CNC routers are adaptable to different production needs.

Unlike traditional manual routers, CNC routers can handle complex and intricate designs with ease. These machines can perform 2D and 3D cuts with exceptional accuracy. Their ability to engrave fine details, create curved surfaces, and handle geometric shapes makes them ideal for tasks such as:

Wood carvings

Aerospace components

Custom signage and logos

Prototype development

Whether the task involves detailed engraving or precision cutting, CNC routers can adapt to different types of work without compromising the quality of the final product.

One of the key strengths of CNC routers is their ability to easily adapt to custom jobs. The machine’s software can be reprogrammed to adjust for different designs or specifications, making them perfect for bespoke projects. This level of customization is crucial for industries like:

Sign-making: Where businesses need to produce unique, one-off designs for clients.

Custom Furniture Design: Where every project may require a slightly different set of cuts or dimensions.

Prototyping: In industries like aerospace and automotive, where design concepts need to be tested before full-scale production.

CNC routers allow manufacturers to switch between different projects or designs quickly, making them perfect for companies that focus on custom work or low-volume production runs.

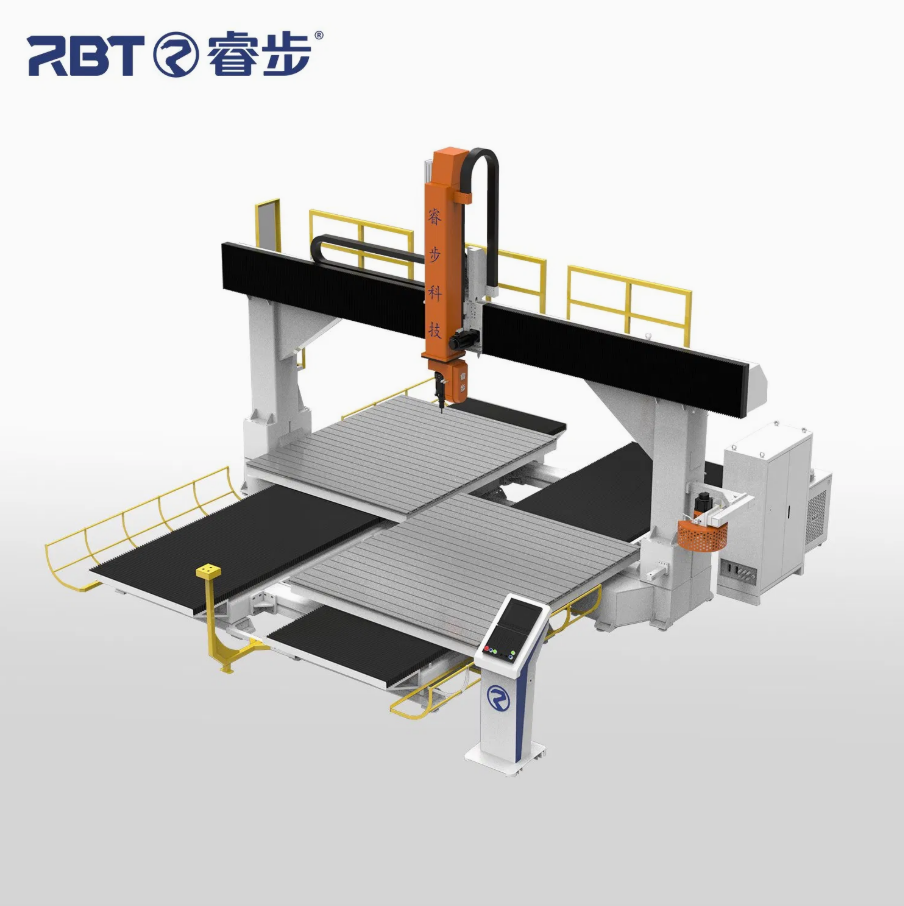

Traditional routers are generally limited to operating along three axes: X, Y, and Z. However, advanced CNC routers can work along multiple axes (e.g., 4-axis, 5-axis), allowing them to cut, engrave, and shape materials from various angles. This multi-axis capability makes CNC routers ideal for 3D shaping and tasks that require more dynamic movement.

For example, a 5-axis CNC router can cut materials at multiple angles simultaneously, enabling it to produce highly complex shapes that would be difficult or impossible to achieve with a manual router. This versatility opens the door to more intricate designs and a broader range of applications, particularly in industries like aerospace and automotive, where precision is critical.

In woodworking, CNC routers are used to cut, carve, and shape wood with precision. They are essential in furniture production, cabinet making, and decorative carving, allowing manufacturers to produce custom designs at scale. CNC routers allow for intricate designs in wooden furniture, doors, and flooring, ensuring consistent results and high-quality finishes.

CNC routers are crucial in the sign-making industry, where companies produce customized signage for businesses. Whether it's for 3D logos, engravings, or cut-out lettering, CNC routers enable the creation of eye-catching and precise designs that attract customers.

CNC routers are also highly effective for cutting and engraving plastics and acrylics, which are commonly used for displays, custom parts, and signs. Their ability to create smooth edges and intricate designs makes them ideal for projects requiring aesthetic appeal and functionality.

CNC router machines are the epitome of efficiency and versatility in modern manufacturing. From their ability to automate production processes to their capacity to work with a wide range of materials, these machines are indispensable in today’s fast-paced industries. Their precision, speed, and adaptability have made them essential tools in woodworking, sign making, and more.

At Fujian RBT Intelligent Equipment Co., Ltd., we specialize in providing high-performance CNC router machines designed to improve efficiency and support customized production. With over 24 years of experience, we offer cutting-edge solutions tailored to meet the diverse needs of our clients, backed by global after-sales service and comprehensive support.

1. How do CNC routers increase efficiency in manufacturing?

CNC routers automate the cutting and shaping process, reducing manual labor and production time. They operate with precision and can run continuously, increasing throughput and efficiency.

2. Can CNC routers be used for materials other than wood?

Yes, CNC routers are versatile and can cut through materials like plastic, acrylic, and composites, making them suitable for various industries.

3. What is the difference between a 3-axis and 5-axis CNC router?

A 3-axis CNC router operates along the X, Y, and Z axes, while a 5-axis router adds two additional rotational axes, allowing for more complex cuts and shapes.

4. How do CNC routers ensure precision and consistency?

CNC routers follow programmed instructions from CAD/CAM software, ensuring that each cut or engraving is executed with exact precision, providing consistent results across multiple parts.