Views: 0 Author: Site Editor Publish Time: 2026-01-27 Origin: Site

A CNC router machine is a powerful tool used in various industries to automate cutting, shaping, and engraving of materials like wood, plastic, and composites. CNC stands for "Computer Numerical Control," which means the machine operates based on a set of pre-programmed instructions provided by CAD (Computer-Aided Design) or CAM (Computer-Aided Manufacturing) software.

This level of automation has revolutionized manufacturing, as it offers unparalleled precision, speed, and efficiency compared to manual processes. But what exactly does a CNC router machine do, and why is it so important in modern manufacturing? Let’s dive into the specifics.

A CNC router works by following a digital design file to precisely control the movement of the router head and cutting tools. These machines typically operate along three axes: X, Y, and Z, which correspond to the movement along horizontal, vertical, and depth directions.

Once the design is ready, the machine’s controller interprets the instructions and moves the router head accordingly, cutting or engraving the material to create the desired product.

A CNC router consists of several components that work together to achieve high precision and efficiency:

Controller: This is the brain of the CNC machine, interpreting the code from the CAD/CAM software and instructing the machine on how to move.

Spindle: The spindle holds and powers the cutting tool, allowing it to rotate and interact with the material.

Axes: The movement of the router head is controlled along the X, Y, and Z axes. Some CNC routers also feature additional rotational axes (4th and 5th) for complex tasks.

Cutting Tools: These are the tools that make contact with the material, and they can vary depending on the type of work being done, from basic end mills to specialized engraving bits.

CNC routers are a staple in woodworking and furniture production. They are used to create everything from intricate wood carvings and furniture components to large custom wood panels. The ability to automate processes such as cutting, engraving, and shaping allows manufacturers to produce detailed designs efficiently and with minimal waste.

Some common woodworking applications for CNC routers include:

Cabinet Making

Custom Furniture Design

Flooring and Panel Production

Wood Carving and Engraving

CNC routers are also widely used in industries that deal with plastics and acrylics. They are used to cut and shape sheets of plastic for signage, display cases, and custom parts for electronic devices, including casings and housings.

One of the most common uses of CNC routers is in the sign-making industry. CNC routers are capable of cutting, engraving, and shaping various materials like wood, acrylic, to create signs, logos, and promotional materials. The level of detail achievable makes CNC routers ideal for creating both 2D and 3D designs, ensuring the end product is both professional and durable.

CNC routers are known for their exceptional accuracy, capable of producing parts with tolerances as tight as a few thousandths of an inch. This high level of precision is especially important for industries that require intricate designs or functional components that must fit together perfectly.

By automating the cutting and engraving process, CNC routers significantly reduce the time and effort required for production. Once the machine is set up and programmed, it can operate continuously with minimal human intervention, allowing for faster turnaround times and consistent results.

CNC routers can handle a wide range of materials, including wood, plastics, and composites. This versatility makes them suitable for a variety of industries, from furniture production to aerospace manufacturing. Additionally, CNC routers can easily switch between different tasks or materials, offering manufacturers the flexibility to adapt to changing customer demands.

Although CNC routers can be expensive upfront, they reduce long-term costs by lowering labor expenses, minimizing material waste, and improving production speed. With a CNC router, businesses can achieve higher output with fewer errors, reducing overall production costs.

The 3-axis CNC router is the most common type, operating along the X, Y, and Z axes. It’s ideal for basic cutting, engraving, and shaping tasks on flat surfaces. This type of router is commonly used in woodworking, plastics, and signage industries.

The 4-axis CNC router adds an additional rotational axis (the A-axis), allowing the router to cut or engrave more complex shapes, including cylindrical and curved surfaces. This makes it ideal for more detailed or intricate parts that require multiple angles of cutting.

The 5-axis CNC router can rotate in five directions, making it one of the most advanced types of CNC routers. This added flexibility enables the router to perform highly complex tasks, such as cutting parts with irregular shapes or intricate designs. The aerospace and automotive industries commonly use 5-axis routers for parts that require extreme precision.

Regular maintenance is key to ensuring that a CNC router operates at peak performance. Here are some important maintenance practices:

Lubrication: Regularly lubricate moving parts to prevent wear and tear.

Dust and Debris Removal: Clean the machine to remove dust and debris that can affect performance and accuracy.

Tool Inspection: Regularly check and replace cutting tools that have become worn or damaged.

Software Updates: Keep the software up to date to improve functionality and ensure compatibility with the latest CAD/CAM systems.

CNC router machines are transformative tools that bring automation, precision, and versatility to manufacturing processes. Whether it’s in woodworking, plastic fabrication, or sign making, CNC routers enable industries to produce high-quality products with efficiency and accuracy.

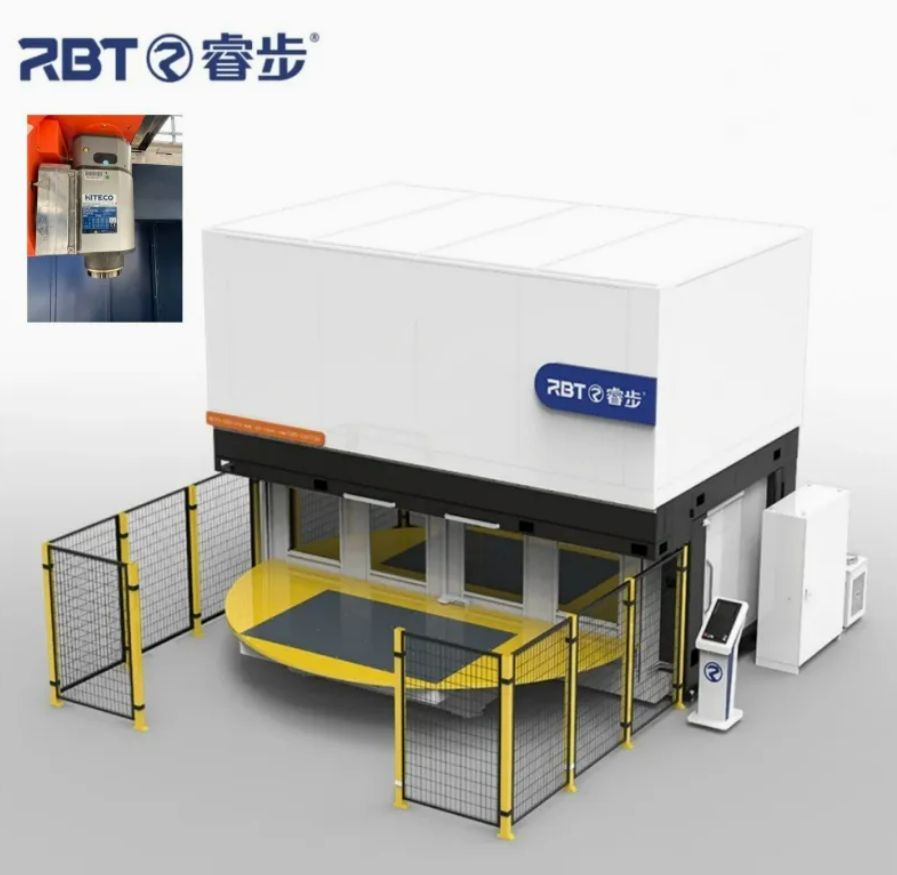

At Fujian RBT Intelligent Equipment Co., Ltd., we specialize in providing high-performance CNC routers that meet the diverse needs of modern manufacturing. Our machines are designed with the latest technology to offer unbeatable quality, precision, and reliability, ensuring that our customers remain at the forefront of their industries.

1. What materials can a CNC router machine cut?

A CNC router can cut wood, plastic, composites, acrylic, and more, making it a versatile tool for various industries.

2. How does a CNC router differ from a regular router?

Unlike a manual router, a CNC router is automated and uses a computer to follow precise cutting patterns, offering higher accuracy and efficiency.

3. What is the difference between a 3-axis, 4-axis, and 5-axis CNC router?

A 3-axis router operates on X, Y, and Z axes, while a 4-axis router adds a rotational axis (A-axis). A 5-axis router offers even more rotational movement, making it ideal for complex tasks.

4. Can CNC routers be used for engraving?

Yes, CNC routers are frequently used for engraving intricate designs and patterns on materials like wood and plastic.