Views: 0 Author: Site Editor Publish Time: 2026-01-29 Origin: Site

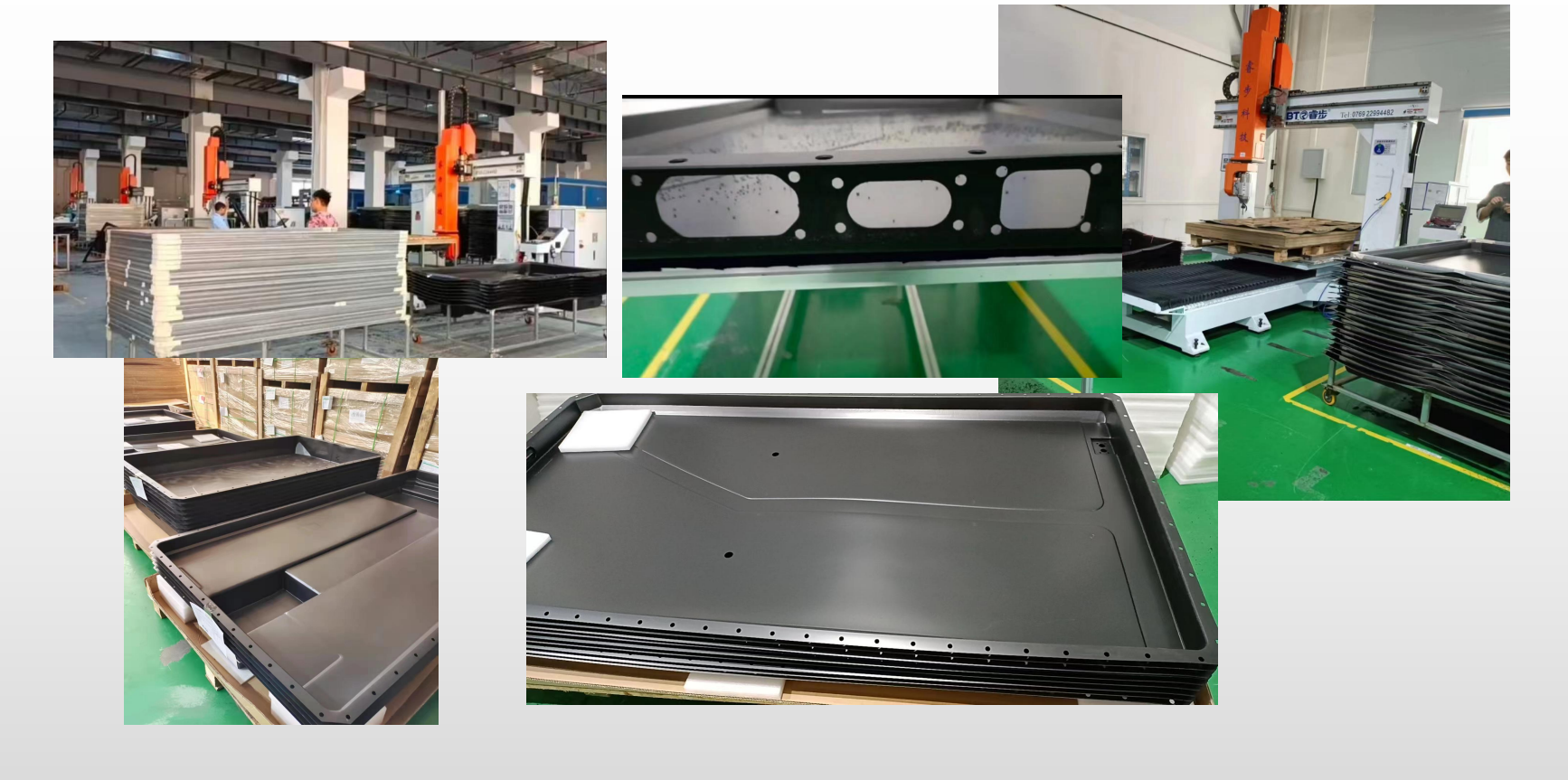

CNC router machines are at the forefront of modern manufacturing, offering precise and efficient solutions for cutting, engraving, and shaping materials. "CNC" stands for Computer Numerical Control, and these machines are powered by computer programs that guide them through the manufacturing process, ensuring accuracy and consistency. Whether it’s for woodworking,plastics, or composites, CNC routers have proven their importance in enhancing productivity across various industries.

But what makes these machines stand out? What are the real benefits of using CNC routers in manufacturing? In this article, we will explore the top benefits that CNC router machines bring to the table.

One of the most significant advantages of CNC router machines is their precision. The machines are controlled by CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software, allowing for highly accurate cuts, engravings, and designs. Unlike manual routers, which rely on the skill of the operator, CNC routers consistently produce products with tight tolerances.

For industries like aerospace, automotive, and electronics, where precision is critical, CNC routers are indispensable. These machines ensure that every part is cut exactly to specifications, significantly reducing errors and minimizing the need for rework.

CNC routers can maintain the same level of precision regardless of how many parts are produced. This consistency is vital for high-volume production, where each item must meet the exact same standards.

In traditional manufacturing, operators often spend significant time adjusting machines, manually guiding cutting tools, and monitoring the process. With CNC routers, once the design and program are set up, the machine can operate autonomously, significantly reducing the time spent on each task. Whether it’s cutting complex shapes or engraving fine details, CNC routers complete tasks much faster than manual methods.

This boost in speed translates into shorter lead times, which is crucial in industries where fast turnaround is essential, such as custom furniture production or sign making.

Since CNC routers are automated, they can work around the clock with minimal human intervention. This leads to continuous production, especially in industrial settings where there’s a need to maximize output.

Another key benefit of CNC router machines is their versatility. These machines can work with a wide variety of materials, including:

Wood: For cabinetry, furniture, and custom designs.

Plastics and Acrylics: For signage, displays, and parts for electronics.

Composites: For specialized applications in industries like aviation and marine.

CNC routers are equipped with different tools and settings that allow them to work with soft and hard materials alike, making them suitable for various industries. This flexibility makes CNC routers an invaluable investment for businesses looking to work with multiple materials.

CNC routers don’t just cut and shape—these machines can also engrave intricate patterns, carve designs, and perform 3D milling, making them perfect for both functional and decorative tasks. This capability is essential for industries like signage, furniture design, and custom part manufacturing.

Human error is always a risk in manual operations, particularly in intricate tasks that require a high level of skill. With CNC routers, errors caused by fatigue, inattention, or miscalculations are significantly reduced. Since the machine follows the exact instructions from the program, there’s minimal chance of deviation or mistakes during production.

For manufacturers producing large quantities of the same product, CNC routers ensure uniformity. Every part produced is identical to the last, reducing the likelihood of defects and ensuring the consistent high-quality standards required by many industries, such as medical device manufacturing or electronics assembly.

Although the initial investment in CNC router machines can be high, they offer significant cost savings in the long run. These machines require fewer operators and less manual labor, which translates into lower labor costs. This also allows businesses to allocate resources to other areas, such as design or customer service.

CNC routers optimize material usage by cutting parts with precision, ensuring minimal waste. Since the router follows the exact cutting paths, manufacturers don’t need to worry about over-cutting or wasting materials. Over time, this material savings can add up, making the overall production process more efficient and cost-effective.

Due to the high precision of CNC routers, the likelihood of having to redo or repair parts is minimized. This reduces the costs associated with rework and ensures that products are finished on time and to specification.

One of the standout features of CNC routers is their ability to adapt to design changes quickly. If a customer requests a modification or if the design needs to be adjusted, operators can simply update the CAD file and reprogram the CNC machine accordingly. This flexibility is especially important for industries that rely on custom products, such as:

Custom furniture design

Personalized signage

One-off prototype production

CNC routers can easily handle custom designs, allowing businesses to meet specific customer demands without starting from scratch.

CNC routers reduce the risks associated with manual labor by automating the cutting and engraving processes. Operators are not exposed to moving parts or sharp tools, significantly reducing the chances of workplace injuries. Additionally, many modern CNC routers come with built-in safety features, including emergency stop buttons and automatic shutdown systems.

While CNC routers require initial programming and setup, once the machine is running, the operation is relatively straightforward. Many modern CNC routers come with intuitive control panels, and operators can monitor the machine’s progress in real time. This user-friendliness makes CNC routers accessible even for businesses with limited technical expertise.

CNC routers are perfect for scaling operations. If a business needs to increase production volume, it can do so without requiring significant changes to the manufacturing process. Since the machine is capable of working continuously and autonomously, scaling up production becomes much easier compared to manual methods.

CNC routers can handle both small-scale, high-detail jobs and large, industrial projects. Whether it’s producing small custom parts or cutting large panels for construction, CNC routers can adapt to the scale of the job without compromising quality.

CNC router machines offer numerous benefits, making them essential in modern manufacturing processes. From improved precision and faster production times to reduced human error and material waste, CNC routers provide unparalleled advantages for businesses across a wide range of industries.

At Fujian RBT Intelligent Equipment Co., Ltd., we offer cutting-edge CNC routers that bring these benefits to life. With over 24 years of experience, we are committed to providing high-quality, customizable CNC solutions that help our clients improve efficiency, reduce costs, and stay ahead in their respective markets.

1. What industries use CNC routers?

CNC routers are widely used in industries like woodworking, automotive, aerospace, and custom part manufacturing.

2. Can CNC routers cut materials other than wood?

Yes, CNC routers can cut wood, plastic, acrylic, and composites, making them versatile tools for various applications.

3. How does a CNC router reduce labor costs?

By automating the cutting and engraving processes, CNC routers reduce the need for manual labor and increase productivity, ultimately lowering labor costs.

4. How does CNC routing increase production efficiency?

CNC routers can work continuously, follow precise instructions, and perform tasks faster than manual methods, increasing overall production efficiency.

5. Are CNC routers safe to use?

Yes, CNC routers are designed with safety features, such as emergency stops and protective enclosures, reducing the risk of accidents and providing a safer work environment.