Views: 0 Author: Site Editor Publish Time: 2025-12-05 Origin: Site

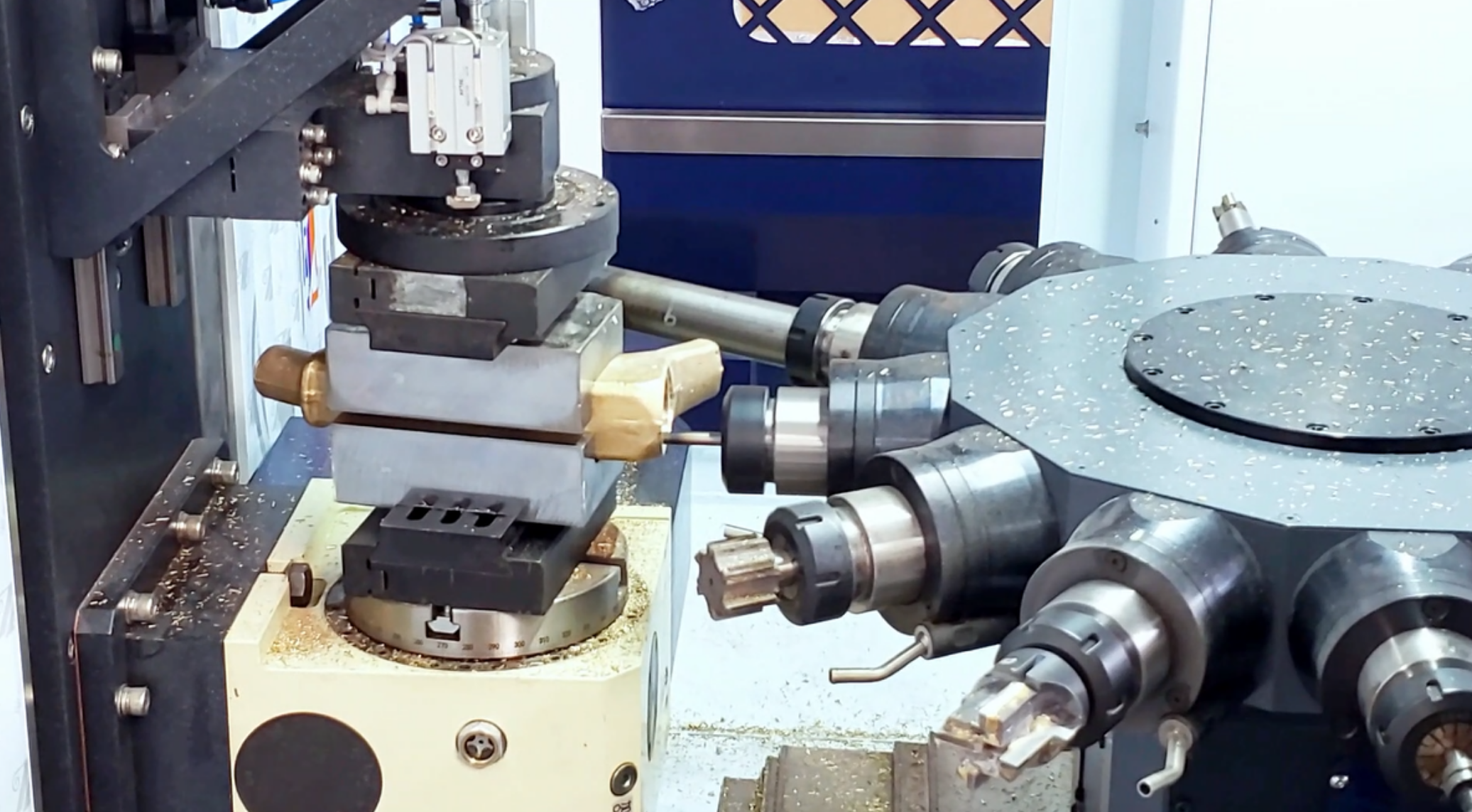

Modern manufacturing has entered a new era defined by digital intelligence, automation, and extreme precision. Among all machining technologies, the 5-axis CNC machining center has become the gold standard for complex part production, enabling faster, more flexible, and more accurate processing than traditional 3-axis systems. From aerospace turbines to automotive structural parts, from medical devices to composite-material molds, the rise of 5 axis cnc machine solutions is reshaping global industrial capabilities.

A 5-axis cnc machining center differs fundamentally from conventional machining tools because it can move a tool or workpiece along five independent axes simultaneously. This includes the standard X, Y, and Z linear motions, plus two additional rotary motions. The result is an advanced machining method capable of reaching multiple faces of a part without manual repositioning. For manufacturers seeking efficiency, consistency, and tight tolerances, 5-axis cnc technology is no longer an option—it's a competitive necessity.

As industries continue to adopt composite materials, lightweight structures, and complex geometries, the role of manufacturers like Fujian RBT Intelligent Equipment Co., Ltd. becomes increasingly important. With strong engineering capability, automation expertise, and deep manufacturing experience, RBT stands among the leading CNC machining center suppliers, delivering machines designed to maximize performance and long-term reliability.

A 5-axis cnc machine is defined by its ability to move the cutting tool and the part in more directions than conventional machining centers. While a standard machine moves only in three linear axes, a 5-axis cnc machining center adds rotations that allow the tool to approach the workpiece from virtually any angle.

The machine can coordinate movements along five axes at once, enabling smooth, continuous cutting across complex surfaces. This capability eliminates the need for repositioning the part manually, reducing both labor time and the risk of dimensional errors.

The two rotational axes enable the cutting tool to tilt toward the workpiece. This makes it possible to:

Create undercuts

Machine deep cavities

Maintain consistent tool angles

Reduce tool vibration

Improve surface quality

This alone allows manufacturers to reach levels of geometry that are impossible on a traditional machining center.

Because the part does not need to be moved between multiple fixtures, production becomes significantly more efficient. A single setup can complete operations that previously required multiple machining stages.

Every manual reposition introduces new tolerance errors. By machining in a single setup, a 5 axis cnc machine maintains perfect alignment between operations, ensuring higher dimensional accuracy.

Industries that rely on precision—such as aviation, medical, and mold-making—depend heavily on 5-axis cnc machining because it maintains stability even for components with tight tolerances and curved organic shapes.

To understand how a 5-axis cnc machining center works, we must examine both the mechanical structure and the intelligent control systems that drive it.

A typical 5-axis CNC machine includes:

Three linear axes (X, Y, Z) – controlling movement across length, width, and height

Two rotary axes (A, B, or C) – allowing the tool or workpiece to tilt and rotate

Depending on machine design, rotation occurs either in the spindle head (head-tilting type), the table (table-tilting type), or a hybrid combination.

The controller continuously calculates thousands of toolpath points per second. Using advanced interpolation algorithms, the system adjusts speed, tool angle, and cutting depth in real time. This is what allows simultaneous machining of multi-curved surfaces with smooth transitions and minimal manual intervention.

5-axis machining relies on high-level CAD/CAM software. The operator imports a 3D model, selects machining strategies, and generates toolpaths optimized for multi-axis movement. The software then communicates with the CNC controller to execute commands precisely.

To maintain accuracy, the machine performs automatic compensation for:

Thermal growth

Tool wear

Spindle load

Motion lag

Vibrations

This ensures consistent quality even during long production cycles.

Modern 5-axis machining centers integrate sensors and monitoring systems that deliver real-time feedback on spindle conditions, vibration levels, and tool health. This smart capability greatly increases stability and operating reliability.

The shift toward complex geometries, lightweight designs, and integrated components has forced industries to go beyond traditional machining. A 5 axis cnc machining center delivers unmatched capability by enabling:

Eliminating manual repositioning dramatically reduces machining time.

Tool tilt optimization reduces marks and ensures smooth surfaces even on curved geometries.

Continuous machining in one setup eliminates multi-fixture errors.

From metals to composites, plastics, and engineered materials, the machine maintains performance in diverse production environments.

Better tool engagement angles reduce stress on cutting edges and extend tool life.

Because of its versatility and accuracy, a 5 axis cnc machine is widely used in:

Aerospace: turbine blades, structural components

Automotive: engine parts, molds, transmission components

Medical: implants, surgical tools

Energy: impellers, pumps

Electronics: precision housings

Mold & Die manufacturing

Composite-material processing

Wherever complex geometries and tight tolerances matter, the 5 axis cnc machining center becomes indispensable.

As a manufacturer deeply rooted in CNC innovation, Fujian RBT Intelligent Equipment Co., Ltd. has built its reputation by designing advanced machining centers that deliver exceptional precision, stability, and production efficiency. RBT integrates intelligent automation, robust mechanical engineering, and refined control technology to support industries that demand high-performance manufacturing.

A 5-axis CNC machining center represents the highest level of precision manufacturing, enabling complex geometries, faster production cycles, and superior accuracy across a wide range of industries. Through advanced engineering, intelligent control systems, and robust automation technologies, manufacturers like Fujian RBT Intelligent Equipment Co., Ltd.are helping global industries stay competitive in an era defined by smart manufacturing and efficiency.

By integrating innovation, structural stability, and global service capability, RBT continues to deliver trusted solutions that empower companies to achieve higher precision and productivity.

1. What is the main advantage of a 5 axis CNC machine?

It allows machining from multiple angles in one setup, reducing time and improving accuracy.

2. Can a 5-axis machining center handle composite materials?

Yes. Advanced machines like those from RBT are designed for composite machining with stable edge quality and minimal vibration.

3. Is programming for 5-axis CNC complicated?

5-axis programming requires CAD/CAM software, but automation and toolpath optimization simplify the workflow.

4. What industries benefit most from 5-axis CNC machining?

Aerospace, automotive, medical, energy, mold-making, and electronics rely heavily on 5-axis machining for precision parts.

5. Why choose Fujian RBT Intelligent Equipment Co., Ltd.?

RBT offers high-rigidity structures, intelligent control systems, composite-ready machining capability, and strong global service support.