Views: 0 Author: Site Editor Publish Time: 2026-01-16 Origin: Site

A 5 axis CNC router is one of the most advanced computer-controlled machining tools used across manufacturing industries today. Unlike traditional 3-axis machines that only move along X, Y, and Z directions, a 5-axis system adds two additional rotational axes. This major enhancement allows manufacturers to machine highly complex, multi-dimensional components in a single setup with exceptional precision, reduced handling, and significantly faster production speeds. As industries push for tighter tolerances, intricate geometries, and higher productivity, the 5 axis CNC router has become a crucial solution for modern fabrication.

From aerospace components to automotive molds, large composite parts, and precision woodworking, the 5 axis CNC router provides unparalleled freedom in milling, cutting, drilling, and shaping. In this article, we will dive deep into what a 5 axis CNC router machine is, how it works, its configurations, applications, advantages, limitations, and what to consider when selecting one. Whether you are new to CNC technology or looking to upgrade to advanced 5 axis CNC routing, this comprehensive guide will explain everything you need to know.

CNC routing refers to the automated machining process controlled by computer numerical code. A router cuts or shapes materials based on a programmed toolpath, allowing for repeatable, accurate, and efficient production. CNC routers are used in woodworking, plastics, metals, foams, composites, and other engineered materials.

Traditional CNC routers include:

X-axis: left to right

Y-axis: front to back

Z-axis: up and down

A 5 axis CNC router adds:

A-axis: rotation around the X-axis

B-axis: rotation around the Y-axis

The result: the cutting tool can approach the workpiece from virtually any angle. This flexibility is extremely valuable for producing undercuts, deep cavities, compound curves, and free-form surfaces that are impossible or inefficient on 3-axis systems.

A 5 axis CNC routing system integrates precision mechanics, servo motors, motion controllers, CAD/CAM software, and a spindle. Here's how the process typically works:

The operator creates a 3D model in CAD software such as SolidWorks, Rhino, or Fusion 360.

CAM software generates toolpaths specifically for 5-axis machining. These toolpaths include synchronized linear and rotary movements to achieve complex angles.

The operator sets:

workpiece zero point

tool length offsets

fixture coordinates

rotational pivot points

During machining, the controller continuously adjusts both linear and rotary axes, allowing the spindle to maintain optimal cutting orientation. As a result, the cutter can follow curved shapes, deep pockets, or multi-sided geometries without requiring manual repositioning.

Most 5-axis parts come off the machine nearly complete due to its ability to reach all sides in one process.

Different 5-axis systems use various mechanical layouts. The two most common categories are:

In this design, the table remains stationary while the spindle head rotates and tilts. This is ideal for large or heavy workpieces because the material does not need to shift.

Common for:

composite machining

mold making

aerospace panels

The machine uses a rotating or tilting table to manipulate the workpiece.

Advantages:

excellent for multi-sided machining

higher accuracy for smaller components

Used widely in:

metalworking

prototyping

jewelry and precision parts

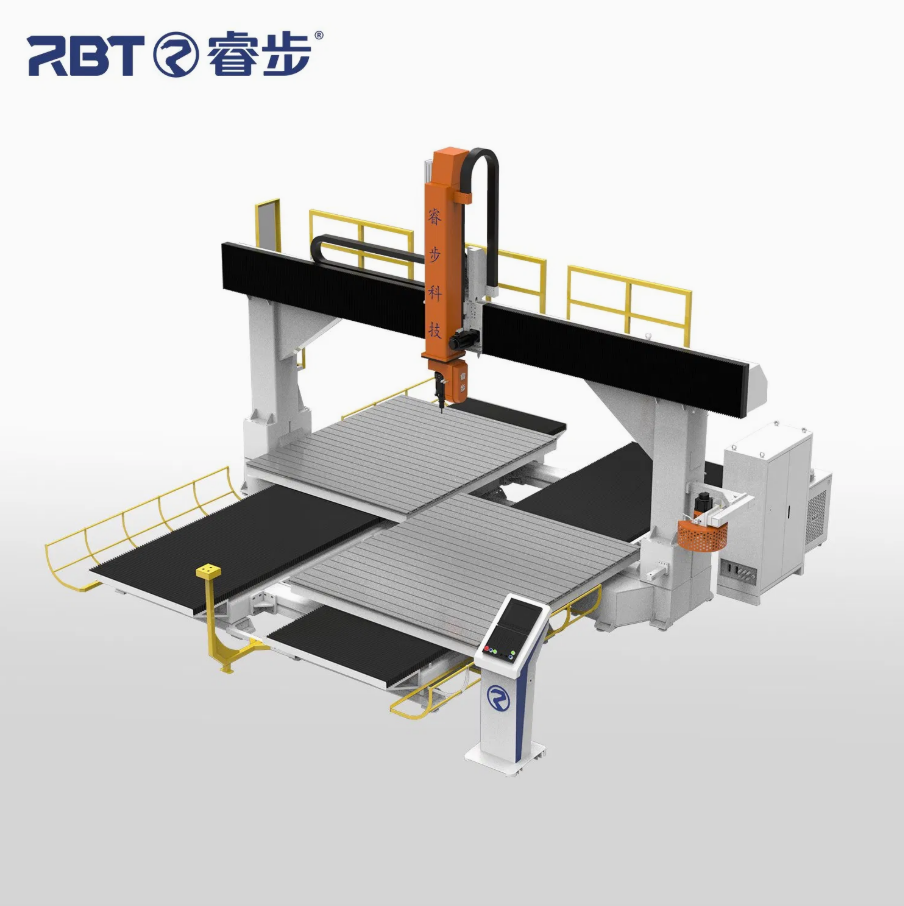

A high-rigidity gantry spans the work area, with a multi-axis head performing the rotational movements.

Benefits:

excellent stability

large cutting range

ideal for plastics, foam, composites, wood

A 5 axis CNC router machine is suitable for both soft and hard materials:

Wood

Foam

PVC

Acrylic

ABS

Polyurethane

Carbon fiber sheets

Fiberglass composites

Aluminum

Brass

Copper

High-density tooling board

Engineered stone

Certain steels (depending on spindle and rigidity)

Machining multiple faces or complex contours typically requires several setups on a 3-axis machine. A 5-axis router completes most operations in one go, saving time and reducing error.

Compound angles, undercuts, organic curves, and free-form surfaces are handled naturally with 5-axis movement.

Because the tool can tilt to maintain an optimal cutting angle, it produces smoother finishes with fewer tool marks.

The extra rotational axes help avoid collisions by orienting the tool safely and efficiently.

More angles, fewer setups, less manual handling = dramatically shorter overall machining cycles.

Maintaining correct cutting orientation reduces tool wear, especially when machining metals or composites.

A 5 axis CNC router is widely used across many fields:

wing components

turbine blades

interior panels

composite molds

car body molds

custom dashboards

chassis components

high-precision metal prototypes

boat hull molds

propeller components

fiberglass and carbon fiber structures

sculptural designs

3D carvings

luxury furniture components

complex façades

decorative panels

curved structural elements

jigs and fixtures

automation components

precision tooling

When choosing a 5-axis system, consider these key specifications:

Higher power is needed for metals, while higher RPM works better for plastics and composites.

A rigid frame minimizes vibrations and ensures precision.

Look for systems with:

advanced 5-axis interpolation

smooth surface algorithms

collision detection

support for major CAD/CAM software

High-precision bearings and drives ensure accurate rotation for complex surfaces.

Choose a machine that fits your typical part dimensions with room for growth.

Essential for woodworking, composites, and aluminum machining.

Metal machining often requires mist or liquid cooling.

Automatic tool changers (ATC) greatly enhance efficiency and flexibility.

Although the terms are often used interchangeably, there are differences:

higher spindle speeds

best for wood, plastics, foam, composites

lightweight construction

larger work envelope

lower spindle speeds but higher torque

best for metals

heavy, rigid structure

higher precision

Many manufacturers of composites or large prototypes prefer a 5 axis CNC router machine, while metalworking plants rely more on 5-axis milling centers.

5-axis toolpaths are more complex than 3-axis. Solution: modern CAM software with automated strategies.

A 5-axis router costs more upfront, but efficiency and output justify the investment.

Understanding rotary axes, positioning, and toolpath simulation is essential.

Always simulate toolpaths before running them on the machine.

As industries demand:

more precise parts

lighter materials

complex geometries

shorter turnaround times

The 5 axis CNC router becomes indispensable. Its ability to combine speed, accuracy, and multi-angle machining makes it far superior to older technologies.

Whether you are producing aerospace parts, composite molds, wooden sculptures, or automotive prototypes, a 5 axis CNC router machine dramatically enhances production capabilities and competitive advantage.

Fujian RBT Intelligent Equipment Co., Ltd. is a professional manufacturer of multi-axis CNC machines, specializing in high-precision 5 axis CNC routers for plastics, composites, molds, and aluminum processing. With 24+ years of experience, strong R&D capability, and a modern production base, we provide reliable, customizable CNC solutions backed by global installation, training, and fast after-sales support. RBT is committed to quality, innovation, and helping customers achieve higher efficiency and better machining performance.

1. What materials can a 5 axis CNC router cut?

It can cut wood, plastics, foam, composites, aluminum, brass, and certain steels depending on machine rigidity and spindle type.

2. Is a 5 axis CNC router difficult to operate?

Modern systems with intuitive software make operation easier, but professional training is recommended to ensure safe and efficient use.

3. How does a 5 axis CNC router improve productivity?

By reducing setups, enabling multi-angle machining, shortening cycle times, and improving surface finishes.

4. Can a 5 axis CNC router replace a 3 axis machine?

Not always—3-axis routers are still useful for simple, flat, or repetitive jobs. However, 5-axis machines greatly expand capability and reduce manual labor.

5. What industries use 5 axis CNC routing most often?

Aerospace, automotive, marine, composites manufacturing, woodworking, prototyping, architecture, and industrial tooling.