Views: 0 Author: Site Editor Publish Time: 2026-01-26 Origin: Site

CNC (Computer Numerical Control) router machines are essential tools in modern manufacturing, allowing for precise and automated cutting, shaping, and engraving of a variety of materials. These machines are a crucial part of industries like woodworking, plastics, and even the manufacturing of composite materials.

CNC routers stand apart from traditional routers as they operate using computer-aided design (CAD) and computer-aided manufacturing (CAM) software, which guides the machine's operations. This automation leads to more efficient production processes, greater precision, and a reduction in human error.

CNC routers consist of several key components that work together to perform tasks with extreme accuracy. These components include:

Controller: The heart of a CNC router, the controller receives the code from the CAD/CAM software and translates it into commands that control the machine’s movements.

Spindle/Router: This is the part that holds and operates the cutting tool. The spindle rotates at high speeds to cut through materials.

Axes: Most CNC routers operate on at least three axes: X, Y, and Z. Some advanced models, like 5-axis CNC routers, have additional axes for more complex movements.

Cutting Tools: These are the tools that make physical contact with the material, ranging from simple end mills to complex carving bits.

The process begins when the operator designs a product using CAD software. The design is then converted into G-code using CAM software, which is read by the CNC router controller. The controller then instructs the router to move along the designated paths, cutting, shaping, or engraving the material as per the design.

CNC router machines are incredibly versatile and are used in various industries to meet different production needs.

In the woodworking industry, CNC routers are primarily used for precision cutting and engraving of wood. They can carve intricate designs into furniture, cabinetry, and flooring. Additionally, they are often used in the production of doors, windows, and custom wood products.

CNC routers are also used to cut, shape, and engrave plastic materials. This application is vital in industries that manufacture signage, display panels, and components for electronic devices.

CNC routers are invaluable in the sign-making industry. These machines can carve both 2D and 3D designs into wood, or acrylic, making them ideal for producing signs and logos with sharp details and consistent quality.

CNC router machines are known for their exceptional precision and accuracy. With advanced software and automated operation, these machines can achieve intricate cuts and complex designs that would be nearly impossible with manual tools.

One of the greatest benefits of CNC routers is their automation capabilities. After inputting the design, the machine performs the task without human intervention, allowing for faster production speeds and reduced labor costs.

CNC routers are programmed to replicate the same cutting patterns multiple times without variation. This consistency is crucial for high-volume production, where uniformity is key.

CNC routers can cut a wide range of materials, including wood, plastic, and composites. This versatility makes them suitable for multiple industries and a broad array of applications.

There are several types of CNC router machines available, each designed to meet specific needs.

The 3-axis CNC router is the most common type. It operates along the X, Y, and Z axes to perform cutting tasks. This type of machine is ideal for simpler designs and shallow cuts.

The 4-axis CNC router adds an extra rotational axis to the standard three, allowing for more complex and detailed cutting. It is particularly useful in tasks like engraving on curved surfaces or cutting intricate shapes.

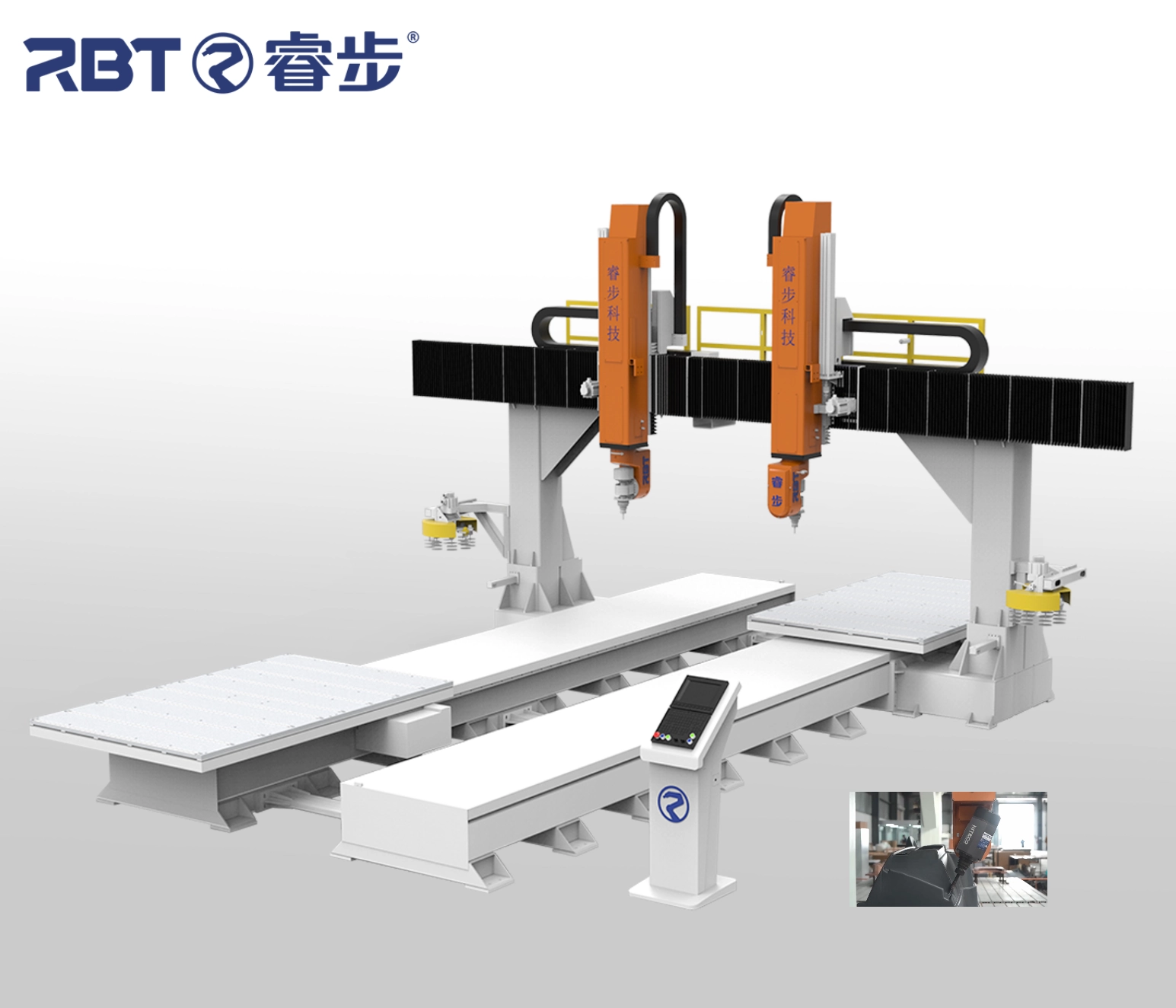

The 5-axis CNC router operates on five axes, which allows it to cut more complex and detailed parts with higher precision. These machines can cut on multiple angles simultaneously, making them essential for industries like aerospace and automotive manufacturing.

Before choosing a CNC router, it’s essential to consider what materials you’ll be cutting. Different machines have different capabilities based on the material, so selecting a machine that is compatible with your materials is key to ensuring optimal performance.

CNC routers come in a range of sizes, from small desktop machines to large industrial units. Choosing the right size depends on the scale of your operations and the size of the materials you intend to work with.

For high-speed production, consider a CNC router that prioritizes speed. However, for intricate designs requiring fine details, precision is key. Some machines allow for easy adjustments between speed and precision based on the project’s requirements.

CNC routers can be complicated to operate, especially for beginners. Look for machines that offer intuitive interfaces, user-friendly software, and comprehensive customer support for troubleshooting and maintenance.

Proper maintenance is essential to ensure the longevity and performance of CNC routers. Here are some key aspects of CNC router maintenance:

Regular Lubrication: Ensure that all moving parts, such as the spindle and axes, are regularly lubricated to prevent wear and tear.

Dust Management: CNC routers produce significant amounts of dust and debris, especially when working with wood. Install dust collection systems to maintain cleanliness and prevent damage to machine components.

Software Updates: Keep the software up to date to ensure compatibility with the latest CAD/CAM technologies and enhance the machine’s functionality.

Tool Inspection: Regularly inspect cutting tools for signs of wear or damage. Dull tools can affect the precision of the cuts and damage the material.

Fujian RBT Intelligent Equipment Co., Ltd. has been at the forefront of CNC machining technology for over 24 years, providing high-quality CNC router machines that deliver superior performance. Our machines are designed for precision, reliability, and versatility, ensuring they meet the diverse needs of industries worldwide.

Whether you're working in woodworking, or plastics, RBT CNC routers are built to offer the best in cutting speed, precision, and durability. We also offer customized solutions tailored to meet your unique production needs, backed by our comprehensive after-sales support network. Choose RBT for your CNC router needs and experience top-tier quality and service.

1. What is a CNC router machine used for?

A CNC router machine is used for automated cutting, engraving, and shaping a variety of materials, including wood, plastic, and composites. It is widely used in industries like woodworking, sign making, and plastic fabrication.

2. How does a CNC router machine work?

A CNC router machine operates by following instructions from CAD/CAM software. It cuts, shapes, and engraves materials by moving along multiple axes (usually X, Y, and Z) to execute precise designs.

3. What are the different types of CNC router machines?

CNC routers come in 3-axis, 4-axis, and 5-axis models. The 3-axis is the most common, while the 4-axis and 5-axis versions offer increased capabilities for more complex and detailed cuts.

4. How much does a CNC router machine cost?

The cost of a CNC router machine varies based on its size, capabilities, and the materials it can handle. Entry-level machines can cost around a few thousand dollars, while high-end industrial machines may range from $20,000 to $100,000 or more.

5. How do I maintain a CNC router machine?

Regular maintenance includes lubrication of moving parts, dust management, software updates, and tool inspection. Proper maintenance ensures the machine operates at peak performance and extends its lifespan.