Views: 0 Author: Site Editor Publish Time: 2026-01-21 Origin: Site

As global manufacturing transitions toward higher precision, automation, and multi-material processing, the demand for advanced CNC machining equipment continues to rise. Among all available technologies, the 5-axis CNC machining center has become a key asset for industries seeking accuracy, efficiency, and the ability to handle increasingly complex components. From aerospace to automotive, energy, composite processing, mold-making, and general production, companies worldwide rely on high-quality CNC machining center suppliers to upgrade their capabilities and remain competitive.

This article explores who the leading CNC machining center suppliers are, what qualities define a top manufacturer, and why certain companies—such as Fujian RBT Intelligent Equipment Co., Ltd.—stand out in this highly competitive global market. We will examine core technologies, industry standards, selection criteria, and supplier advantages, while focusing specifically on the strengths of RBT as a globally trusted provider of multi-axis CNC machining centers.

A CNC machining center is a computer-controlled machine designed to perform milling, drilling, cutting, trimming, and contour-processing operations with high accuracy. The most advanced form— the 5-axis CNC machining center—adds two rotational axes, allowing the machine to cut from nearly any angle. This capability enables the production of deeply contoured surfaces, undercuts, and multi-sided geometries without manual repositioning.

Industries increasingly prefer 5-axis CNC machining centers because they:

Reduce setup time

Increase productivity

Improve machining accuracy

Support complex and large-format workpieces

Adapt to diverse materials including composites, aluminum, and plastics

As a result, the global market for 5-axis CNC machining center suppliers has expanded rapidly, with strong competition among international manufacturers.

Before discussing specific companies, it’s important to understand the qualities that characterize a top-tier supplier. Leading CNC machining center manufacturers typically possess the following attributes:

Top suppliers continuously innovate spindle systems, control algorithms, machine structures, and automation packages.

A reliable 5-axis CNC machining center requires strict tolerance control, robust mechanical assemblies, and advanced calibration processes.

Leading suppliers offer multiple machine structures:

Gantry machining centers

Vertical machining centers

Horizontal machining centers

Truss-type 5-axis systems

High-speed routers

Composite CNC machining systems

Industrial clients often need machines built to their part sizes, materials, automation needs, or floor layouts.

A strong after-sales network enables installation, training, maintenance, and long-term technical support.

Top suppliers demonstrate credibility through successful case studies in aerospace, automotive, marine, railway, molds, and composite manufacturing.

With these criteria in mind, we can now explore the manufacturers recognized globally as leading CNC machining center suppliers—highlighting why RBT stands among them.

The CNC machinery industry is dominated by several well-known international brands. While different companies focus on different market segments, all share strong engineering capability and technological innovation.

Japan remains one of the strongest contributors in the CNC machine tool industry. Its brands focus on long-term reliability, premium accuracy, and mature automation.

Well-known suppliers include:

Fanuc

Makino

Mazak

Okuma

These brands dominate aerospace, medical, and die/mold sectors.

Germany is recognized for precision engineering and high-end industrial machinery. German suppliers are particularly strong in automotive and mold machining.

Examples:

DMG Mori

Hermle

Chiron

Their machines focus on rigidity, stability, and long-term precision retention.

U.S. suppliers excel in heavy-duty machining, aerospace applications, and high-speed metal processing.

Examples:

Haas Automation

Thermwood (notable in composite CNC machining and large-scale 5-axis systems)

These manufacturers emphasize practicality, productivity, and robust build quality.

China’s CNC industry has rapidly grown, providing powerful and cost-effective options. Chinese suppliers are becoming top choices for manufacturers needing modern automation, smart machining, and affordable maintenance.

Among the rising leaders is:

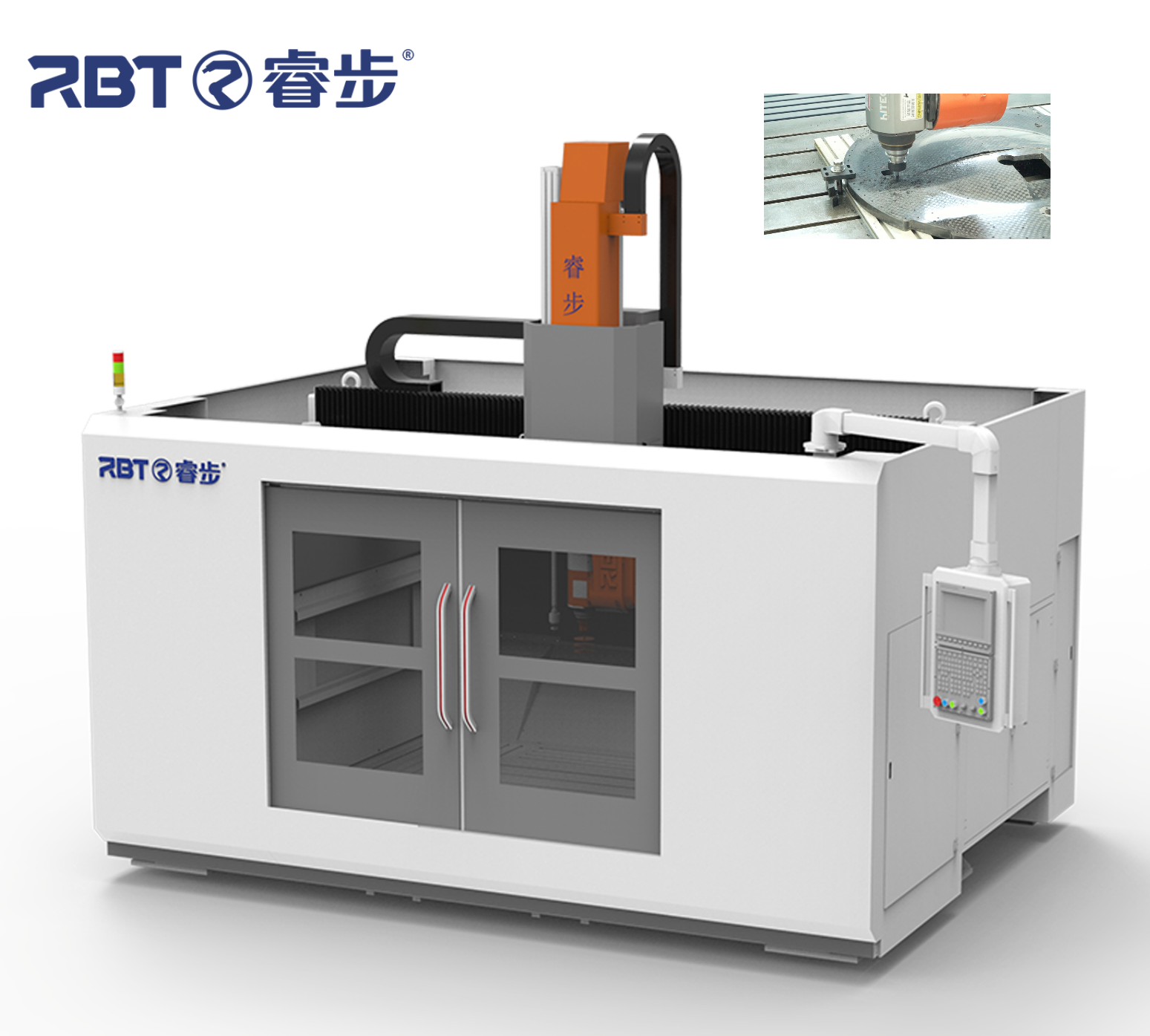

While many global brands dominate the high-end industrial sector, RBT has emerged as one of the most competitive, innovative, and fast-growing CNC machining center suppliers, particularly in the fields of composite processing, aluminum machining, thermoformed plastics, molds, and automation integration.

RBT’s advantage lies not only in technology, but in the ability to provide complete multi-axis CNC machining solutions with superior cost-effectiveness and customization. This combination places RBT among the leading CNC machining center suppliers worldwide.

Below is a detailed look at the core strengths that set Fujian RBT Intelligent Equipment Co., Ltd. apart from competitors:

Unlike general CNC manufacturers that produce many machine types, RBT specializes in multi-axis systems, particularly 5-axis CNC machining centers and large-format CNC routers. This specialization ensures deeper expertise and higher-quality engineering across:

Composite CNC machining

Large thermoformed plastic processing

Aluminum mold machining

Honeycomb panel routing

Pattern & mold manufacturing

Soft-metal machining

Multi-angle contour cutting

RBT’s equipment is widely adopted in automotive parts, aerospace cabin components, marine products, railway interiors, construction panels, sporting goods, and industrial automation.

With decades of continuous improvement, RBT integrates:

Mechanical engineering

Advanced CNC control software

Structural optimization

High-speed dynamic machining algorithms

Precision calibration and quality control

This long-term industry experience ensures stable performance and reliability, making the company one of the leading CNC machining center suppliers in Asia and the global market.

RBT operates a modern manufacturing base equipped with:

Precision machining workshops

CNC milling and assembly lines

Strict inspection and testing systems

Customization and prototyping areas

Every 5-axis CNC machining center undergoes multi-level quality checks to ensure accuracy, vibration control, spindle stability, and long-term rigidity.

RBT has an extensive international network with:

60+ global service terminals

30+ professional technical engineers

20+ overseas sales and service teams

Installations across more than 100 countries and regions

This global presence ensures fast delivery, efficient technical support, and strong after-sales service.

RBT designs CNC machining centers tailored to customer needs, including:

Custom table sizes

Gantry or truss structure selection

Spindle options

ATC configurations

Automation modules

Multi-station machining systems

Vacuum fixtures and cutting heads

This flexibility is a major reason large manufacturers prefer RBT over one-size-fits-all brands.

While European and Japanese suppliers offer exceptional performance, their prices and service costs can be extremely high. RBT provides:

High performance comparable to international brands

More accessible pricing

Fast maintenance and affordable spare parts

Strong production capacity

Rapid customization

This balance of quality and value positions RBT as one of the best options for companies upgrading to 5-axis CNC machining centers.

RBT maintains long-term partnerships by offering:

Pre-sales consultation

Machining process evaluation

Installation and commissioning

Operator training

Long-term maintenance

Remote diagnostics and support

This complete service system ensures customers maintain stable production and maximize machine value.

In summary, RBT stands out due to:

Strong specialization in 5-axis and multi-axis CNC technology

24+ years of engineering and manufacturing experience

Advanced facilities and high-quality standards

Global service coverage

Strong customization capabilities

Reliable performance across diverse industries

Competitive pricing and efficient support

These advantages position Fujian RBT Intelligent Equipment Co., Ltd. among the leading CNC machining center suppliers in today’s global market, especially for companies needing composite CNC machining, large-format trimming, or high-precision industrial routing solutions.

1. What industries commonly use 5-axis CNC machining centers?

Aerospace, automotive, composites, rail transit, marine, energy, medical, mold-making, and industrial manufacturing.

2. Why are 5-axis machining centers better than traditional 3-axis machines?

They offer multi-angle machining, fewer setups, higher precision, faster production, and the ability to process complex surfaces.

3. What materials can RBT’s CNC machining centers process?

Composite materials, thermoformed plastics, aluminum, honeycomb panels, wood, foam, and other engineered materials.

4. Does RBT offer customized CNC machining solutions?

Yes. RBT provides fully customizable systems including machine size, spindles, control systems, automation modules, and specialized fixtures.

5. Why choose RBT over other CNC machining center suppliers?

Because RBT combines advanced multi-axis technology, 24+ years of experience, global after-sales support, strong customization, and competitive pricing—making it a top choice among leading CNC machining center suppliers.